Automated RT-PCR Machines :

End-to-End Guide for High-Throughput, Bias-Free Nucleic-Acid Detection

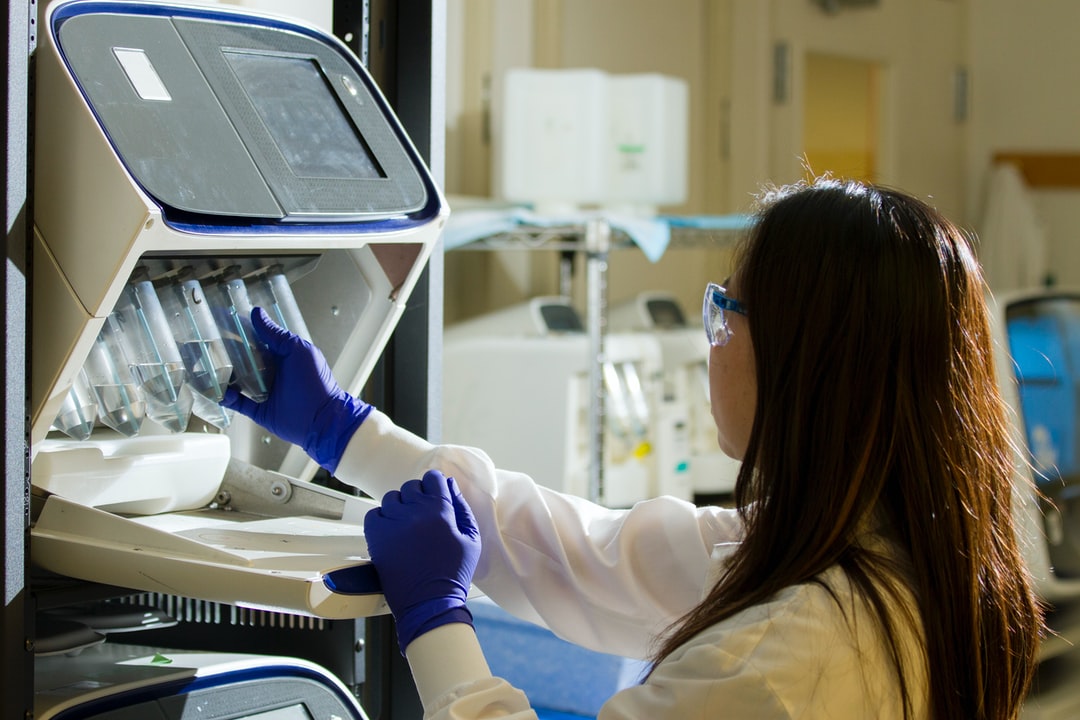

Fully automated real-time reverse-transcription PCR (RT-qPCR) platforms unite liquid-handling robotics, closed-tube chemistry, and integrated data pipelines to deliver thousands of reactions per shift with minimal hands-on time. By collapsing extraction, amplification, and result reporting into a single workflow, laboratories cut turnaround time, standardize quality, and free analysts for deeper data review.

1 | Core Workflow and Hardware Blocks

Academic genomics cores report that this arrangement trims start-to-finish time to < 4 h for 3 000 respiratory or environmental samples, with < 1 % manual interventions.

| Module | Function | Typical Throughput | Inline QC Feature |

|---|---|---|---|

| Automated extraction robot | Magnet-bead RNA/DNA purification in 96- or 384-well plates | ≤ 1 000 samples h⁻¹ | Bar-code scan + process controls |

| Master-mix dispenser | Adds enzymes/primers in <2 min per plate | 3 µL CV ≤ 2 % | Deck temp ≤ 4 °C |

| Plate sealer & centrifuge | Eliminates evaporation / cross-talk | 10 s per plate | Seal integrity check |

| Real-time thermocycler | 40–45 cycles with four optical channels | 384 wells in 60 min | Dual-target internal control |

| LIMS middleware | Pulls Ct values → autoverification rules | ≥ 5 000 results h⁻¹ | Audit-trail + delta-check |

2 | Key Performance Metrics

| Metric | Target | |

|---|---|---|

| Analytical sensitivity (LoD) | ≤ 10 copies µL⁻¹ RNA | |

| Throughput per FTE | ≥ 2 500 reactions shift⁻¹ | |

| Inter-run Ct drift | ≤ 0.5 cycles | |

| Failed extraction rate | < 0.2 % |

3 | Why RCF ≠ RPM in Automation—The “g-force” Analogy

Liquid-handling robots dispense sub-5 µL volumes; excessive stage acceleration shears bubbles into suspensions that inhibit RT-enzyme activity. Vendors specify stage g-force rather than travel speed, echoing rotor RCF logic in centrifuges. Maintaining < 1 × g lateral acceleration keeps CV below 2 % across the deck.

4 | Assay Setup: Designing for Automation

- Master-mix stability – Formulate with hot-start polymerase and trehalose so mix withstands 30 min on-deck at 4 °C without activity loss.

- Primer-probe layout – Align fluorophores to the instrument’s optical channels to avoid bleed-through; literature suggests FAM / HEX / Cy5 / ATTO425 as a conflict-free set.

- Plate map logic – Position extraction-positive, extraction-negative, and no-template controls in quadrants to localize contamination events.

5 | Quality Management (ISO 15189 & 20184 Alignment)

| QA Layer | Daily | Weekly | Monthly |

|---|---|---|---|

| Instrument self-test | ✔ | — | — |

| Extraction positive/negative controls | ✔ per plate | — | — |

| Optics calibration plate | — | ✔ | — |

| External proficiency panel | — | — | ✔ |

ISO 15189:2022 emphasizes documented risk-opportunity logs and corrective-action evidence for every out-of-control event.

6 | Biosafety & Contamination Control

- Directional airflow: Pre-amp room kept at positive pressure; post-amp (plate opening) at negative pressure.

- UV-C hoods & bleach flush: 254 nm lamps for 15 min and 0.5 % sodium-hypochlorite rinse between runs.

- Sealed consumables: Optically clear, pierceable seals reduce aerosol risk during high-speed plate transfers.

CDC nucleic-acid protocols endorse glove changes after plate loading and containment cabinets for any reagent that has seen amplified product.

7 | Digital Integration & “No-Touch” Reporting

Middleware harvests raw fluorescence curves, applies auto-baseline and dynamic threshold, then pushes result objects (Ct, ΔRn, QC flags) into the LIMS. Autoverification logic (all controls pass, Ct within range, delta-check OK) releases > 90 % of routine results instantly; exceptions queue for technologist review. FDA device EUA summaries highlight this closed-data path as a major driver of error reduction.

8 | Scaling Strategies

| Upgrade Path | Benefit | Caveat |

|---|---|---|

| Dual 384-well cyclers | Doubles thermal capacity | Needs faster extraction robot |

| Inline capper/decapper | Removes manual tube handling | Cost, bench space |

| Cloud LIMS + API hooks | Off-site analytics, uptime ≥ 99 % | Robust cybersecurity needed |

High-throughput reviews conclude that integrating capper-decappers and multi-deck robots lifts capacity to > 10 000 reactions per 8-h shift without additional FTEs.

9 | Common Failure Modes & Fixes

| Symptom | Likely Cause | Rapid Remedy |

|---|---|---|

| Control-Ct late by > 1 cycle | Extraction bead carry-over | Add extra wash, increase magnet settle time |

| Edge-well evaporation | Seal temperature too low | Raise heat-seal temp 5 °C |

| Optical channel cross-talk | Fluorophore overlap | Swap probe dye (Cy5 → Quasar 670) |

| High false-positive rate | Aerosol carry-over | Replace tips, UV-sterilize deck, re-map workflow |

10 | Regulatory & Documentation Checklist

- Method verification – Accuracy, precision, LoD, reportable range vs. EUA/CE-IVD kit specs.

- Change control – Any firmware or reagent lot change triggers partial re-validation.

- Audit trail – LIMS must store immutable timestamps, user IDs, raw curves ≥ 5 years (CLIA) or national equivalent.

Automated RT-PCR machines condense extraction, reagent setup, amplification, and data reporting into a single, software-orchestrated workflow, driving throughput beyond manual capacity while locking in reproducibility. Adopting ISO-aligned quality plans, risk-based biosafety, and middleware-driven autoverification turns these instruments into low-touch, high-confidence workhorses for any molecular diagnostics or research facility.